Refitting: ship design review after building.

An example of application of an optimization algorithm for continuous constrained optimization to naval design

Refitting: ship design review after building.

Production of a ship is a very complex task, representing the synthesis of an intense design activity: all the relevant parameters affecting the mission of the ship are considered in this phase. However, some of these parameters are changing in time, i.e. the payload may increase or reduce due to the different market demands: if the variations are not negligible, a review of the project could be economically advantageous after some years, identifying a modification of the hull able to produce an economical saving, higher than the price of the hull modification itself.

The application of numerical optimization techniques for constrained continuous problems is recommended in this case: anexample is here described. The most convenient area for the hull modification has been identified, and a Particle Swarm Optimization (PSO) algorithm has been applied in order to minimize the effective power of the ship at constant speed (10 knots). Classical PSO is here modified in order to improve its efficiency in case of tight constraints: a local search phase is included, and an asynchronous approach is adopted in order to eliminate the evaluation of unfeasible configurations, preserving the parallel structure of the algorithm. Dedicated numerical models are applied for the evaluation of the effective power, and the ship hull modification is produced by using an automatic parametric solid modeler, able to define a new ship hull geometry once a vector of parameters is provided. The new hull shape is forced to have main dimensions not larger than the ones of the original hull, with a maximum variation of the displacement of 1%.

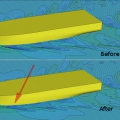

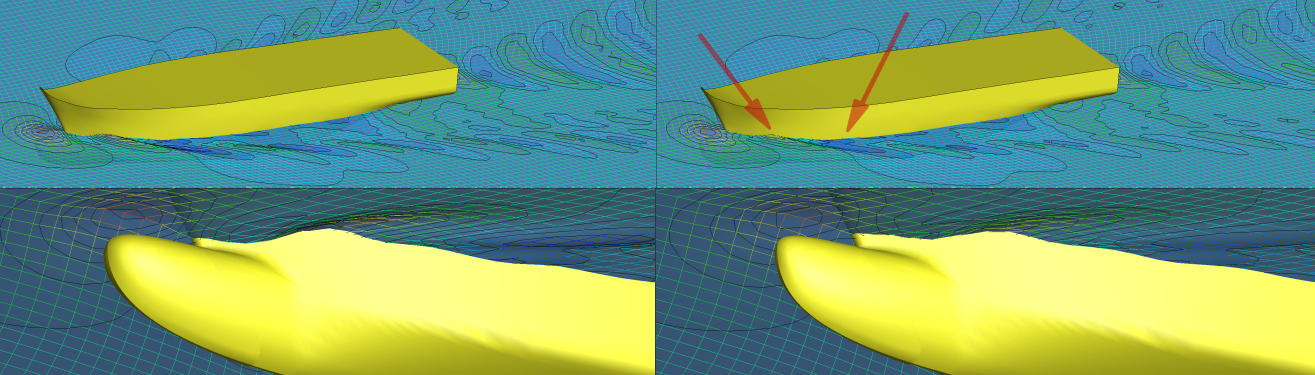

In the picture the wave pattern elevation before and after the modification of the aft part of the ship (the so-called bulbous bow) is reported, and an improvement is evident. On the left part, original bulb geometry and wave pattern. On right, the modified (optimal) bulbous bow and the new wave pattern: a decrease of the wave pattern elevation is obtained on the whole investigated field, with stronger reduction in proximity of the the bow of the ship.

From the economical point of view, the annual cost associated with the fuel consumption has been apprised as 392'000€/year. Fuel consumption reduction obtained after the hull optimization is 4%, that means, a saving of 15'680€/year. The cost of the hull modification, considering the limited interested area, is in between 25'000 and 30'000€: consequently, the Return Of Investment is smaller than 2 years (the hull modification is convenient if the residual life of the ship is longer than 2 years).

Project: "Ottimizzazione, matematica discreta e scienza delle decisioni"

References:

D.Peri, “An inner-point modification of PSO for constrained optimization”, Engineering computations,Vol.32, n. 7, 2005-2019, (2015).

D.Peri, “Conformal Free Form Deformation for the Optimisation of Complex Geometries”,Ship technology research,Vol. 59, 36-41, (2012).